By Steve Kratz, President, Pennsylvania Chemical Industry Council

January 2023

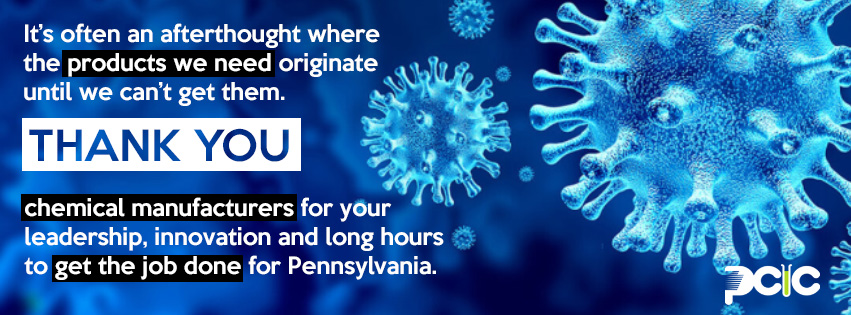

Environmental stewardship and sustainability aren’t routinely spoken in the same breath as the plastics and chemicals industries in general circles. But as members of the Pennsylvania Chemical Industry Council are proving, our industry is leading the charge with innovations in circular manufacturing, production and advanced recycling to create a more sustainable, energy-efficient future.

With more than 30 years serving as the voice of chemical and related industries in the Keystone State, PCIC has supported the growth of the industry largely by highlighting the products our members make and the services they provide that are indispensable to our way of life. Plastics are essential to harnessing renewable energy sources, building more fuel-efficient cars, designing energy-smart buildings and even producing lighter running shoes. We also learned early in the pandemic how critical our industry is as the building block for nearly every medical and health care product we use, ranging from life-saving equipment and infection-protection materials to PPE, disinfectants and sanitizers, and more.

Keenly aware of their vital role in our everyday lives, PCIC members are leading the charge to advance new innovations with a focus on sustainability, circularity and establishing low- or no-carbon goals.